Why Us?

3x SCA Best New Product Award Winner

Industrial Compostable Packaging

Your Very Own White Label Mobile App

Pono Collective: Providing Coffee Education

Lower MOQs With Our Digital Print Process

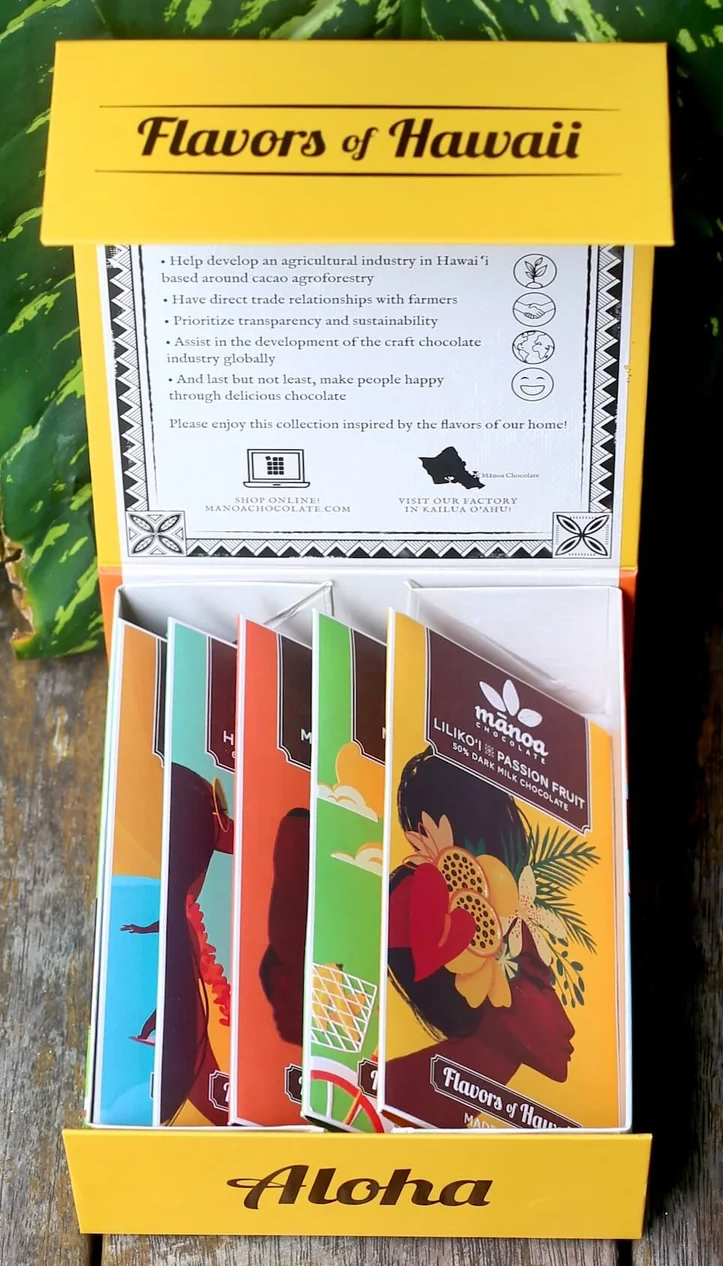

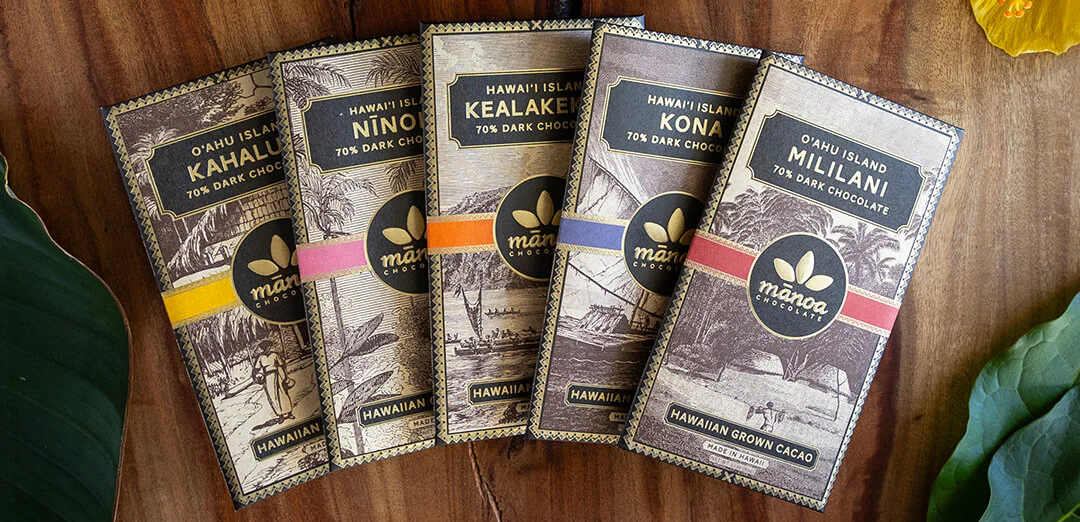

Setting Trends While Elevating Your Brand

| Feature | Coffee Packaging | Chocolate Packaging |

|---|---|---|

| Oxygen Barrier | Essential for flavor preservation | Important to avoid fat bloom |

| Moisture Barrier | Very high; prevents clumping and staleness | Moderate to high; prevents melting or sogginess |

| Light Protection | Often opaque or foil-lined | Foil or tinted film; sometimes visible for aesthetics |

| Degassing Valve | Yes, often required | Rarely, if ever used |

3x SCA Best New Product Award Winner

Industrial Compostable Packaging

Your Very Own White Label Mobile App

Pono Collective: Providing Coffee Education

Lower MOQs With Our Digital Print Process

Setting Trends While Elevating Your Brand