Build A Better Coffee Bag Cycle Today

Every coffee bag tells a story from first print to final disposal. The right choices help your coffee stay fresh, control costs, and cut waste. This guide breaks the Coffee Packaging Life Cycle into three decisions with six clear options. You will see where digital print and rotogravure fit, how compostable packaging and a return program change the end of life path, and how partners like ByFusion and HydroBlox create useful second lives for empty bags. The facts match what brands use today, but the wording is fresh, direct, and easy to follow.

The Life Cycle Map: 3 Decisions You Control

You make three key decisions that shape performance, price, and impact.

1. Production

- Digital print

- Rotogravure print

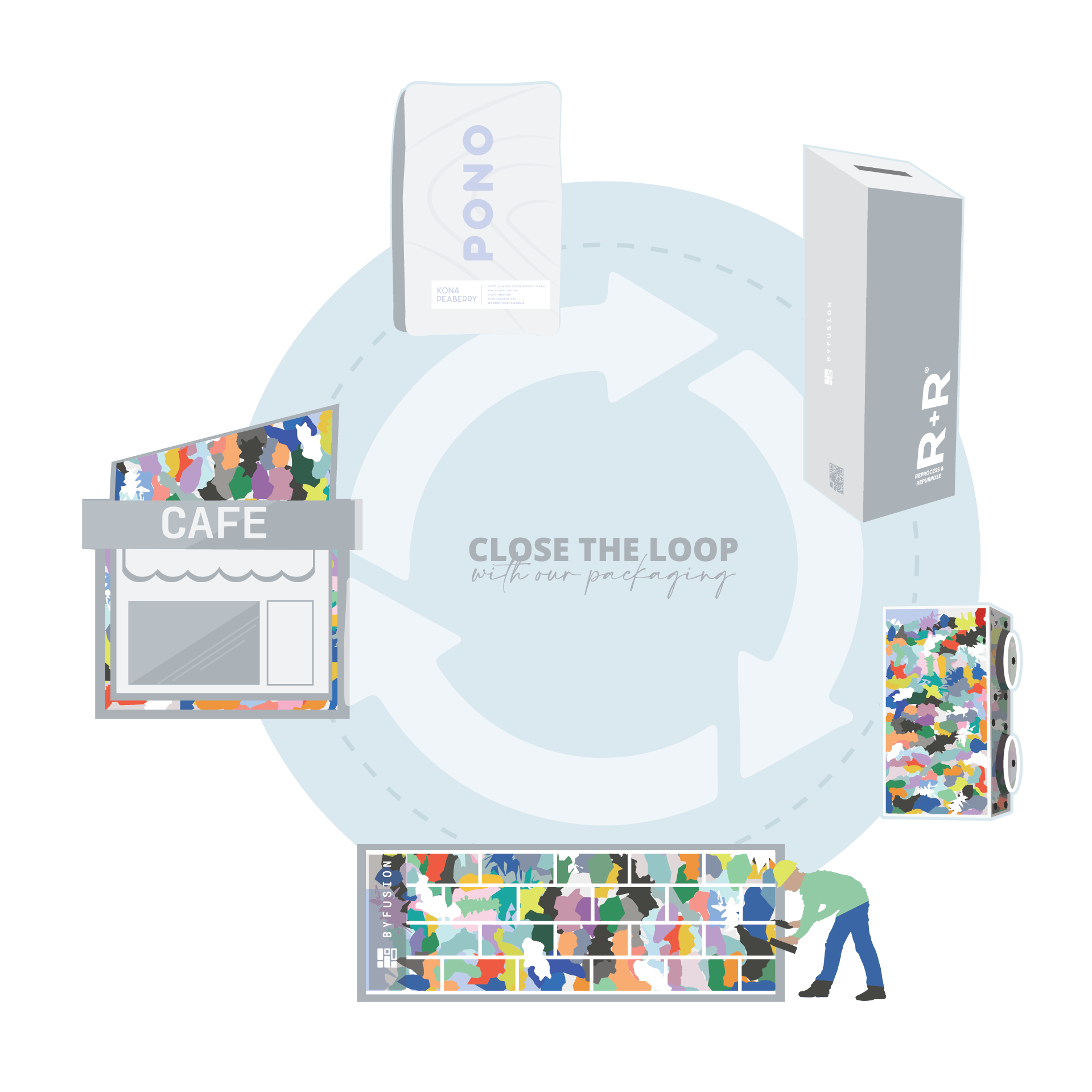

2. End of life path

- Industrial compostable packaging

- Return and Reuse program

3. Eco footprint partners

Each choice affects speed to shelf, artwork flexibility, barrier performance, disposal options, and the story you share with customers.

3x SCA Best New Product Award Winner

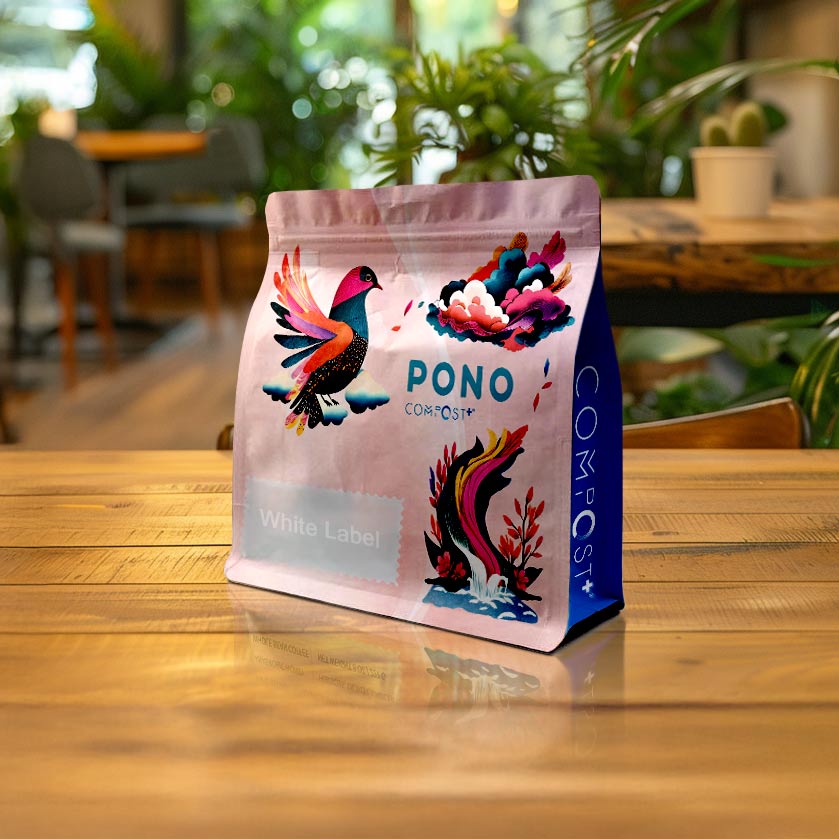

Industrial Compostable Packaging

Your Very Own White Label Mobile App

Pono Collective: Providing Coffee Education

Lower MOQs With Our Digital Print Process

Setting Trends While Elevating Your Brand

3x SCA Best New Product Award Winner

Industrial Compostable Packaging

Your Very Own White Label Mobile App

Pono Collective: Providing Coffee Education

Lower MOQs With Our Digital Print Process

Setting Trends While Elevating Your Brand